Description

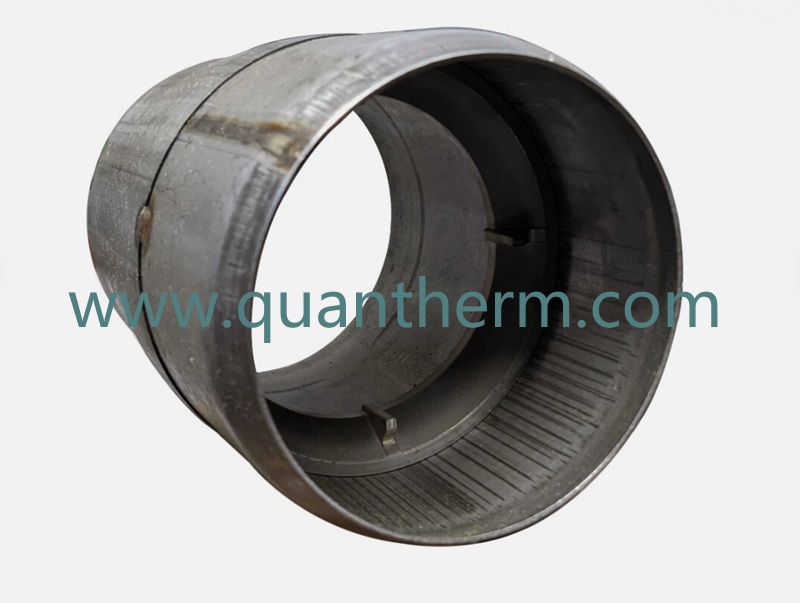

Riello G20 burner flame blast-tube replacement

The Riello G20 burner blast tube is a core component that channels combustion air into the burner’s combustion head. It works with the diffuser to regulate air flow, ensuring proper mixing of air and fuel (gas/oil) for efficient, stable combustion.

Riello G20 burner combustion flame head blast tube

Burner blast tube supports optimal flame formation, enhancing burner performance and reducing emissions in heating applications.

FAQ 1. How to clean and maintain the Riello G20 burner blast tube ?

Safety Preparation

Shut off the burner’s power and fuel supply (gas valve or oil line). Allow the unit to cool completely. Wear gloves and goggles, and gather tools (screwdrivers, brushes, compressed air, soft cloths).

Remove the Blast Tube

Refer to the manual to disassemble the burner housing or combustion head. Loosen fasteners (screws/clips) to extract the blast tube, noting component positions for reinstallation.

Clean the Blast Tube

- Use a stiff brush or copper wire brush to scrub away carbon, dust, and oil deposits from the interior—these block airflow and disrupt fuel-air mixing.

- For stubborn grime, wipe with a cloth dampened in neutral cleaner (e.g., alcohol), rinse, and dry thoroughly (critical for gas models to prevent moisture-related issues).

- Blow out crevices and small holes with low-pressure compressed air to ensure unobstructed airflow.

Inspect and Maintain

Check for cracks, warping, or wear, especially at connections to the diffuser or combustion head. Replace damaged parts with genuine Riello components. Inspect gaskets (if present) and replace 老化 (aged) or cracked ones to prevent leaks.

Reinstall

Reattach the blast tube in reverse order of removal, ensuring secure fitting. Align it with other components (e.g., nozzles, ignition electrodes) as per the manual to preserve airflow and flame stability.

Test and Adjust

Restart the burner and observe the flame (should be steady, with no black smoke or sputtering). Use professional tools to check exhaust temperature and CO emissions if needed. Address anomalies by rechecking installation or consulting a technician.

Notes

Service every 1,000–2,000 operating hours or annually (adjust for dusty environments or poor fuel quality).

Avoid corrosive cleaners to prevent component damage. For gas burners, verify airtightness post-cleaning.

For inexperience, rely on certified technicians to ensure safety and compliance.

+8613906047998

+8613906047998