Description

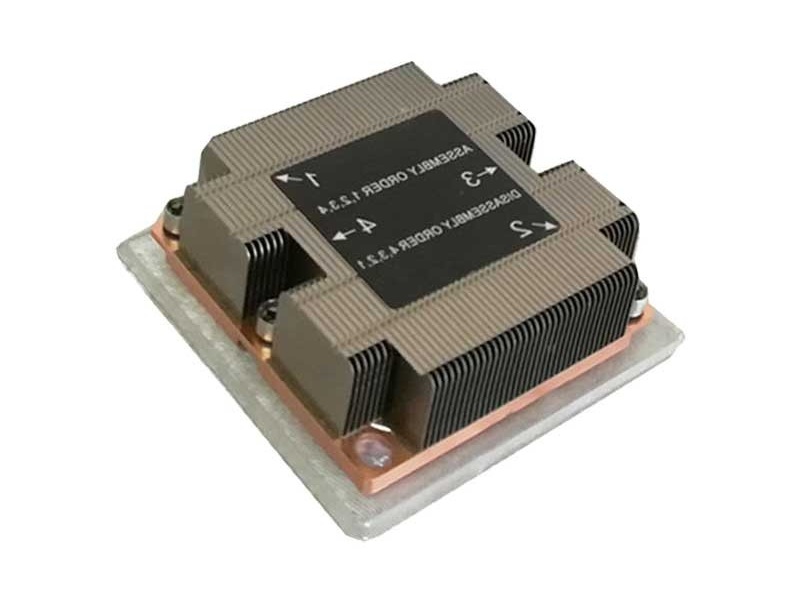

Customized stacked, extruded, finned, aluminum heat sink for engine power generation equipment, solar inverter, PV converter, solar energy, data center server, etc.

- Material: AL6063-T5

- Tolerance: +/-0.1mm

- Delivery time: 2 weeks for samples, 3-4 weeks for production

- Applications: Engine power, photovoltaic inverters, converters, solar energy, automobiles, servers, etc.

Extruded heat sinks are a cost-effective choice with a high degree of automation. Extruded heat sinks are usually made of aluminum, and manufacturers produce fins and bases as a continuous part

Profiles of various shapes are realized by aluminum extrusion process. By changing the shape of the profile, the surface in contact with the air can be changed, thereby changing the heat dissipation capacity. Extruded heat sinks are generally used in medium-power systems with natural convection and forced convection.

Aluminum extruded heat sink process flow:

- Single-piece extrusion molding

- Single-piece press molding

- According to the drawing, CNC machining grooves on the top and bottom to meet flatness requirements

- Surface treatment: degreasing

- Inspection, packaging and shipment

+8613906047998

+8613906047998